How Make Tattoo Power Source

Jason Goodrow, otherwise known every bit "the Goodboy," is a licensed tattoo artist who shares his expertise with the world in his articles.

That's me tattooing.

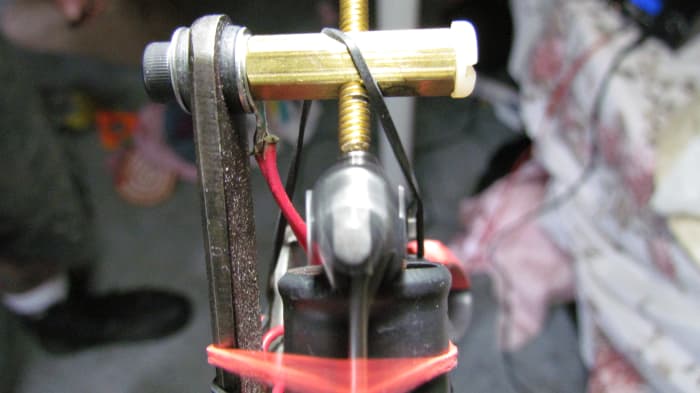

How to Check Your Basic Tattoo Machine

- If you purchased a tattoo kit, it is always best to check your equipment out. You'd be surprised past what you might discover.

- Cheque all the screws on your machine. Over time, vibration tin cause those screws to loosen, which causes faulty running of the machine.

- You should accept a gap of nearly a dime'due south width between the motorcar contact spiral and front jump.

- Finally (and this is a preference if mine), earlier you set up up, take some emery cloth and get over your contact screw a few times. This removes the built-upwards carbon on the stop of contact point and allows for better electrical contact.

This is the power supply model I am currently using. It works as good as the 200 dollar p.s. and saves me $120.

Which Power Supply Should You Use?

There are a ton of power supplies to choose from, but every brand offers the same affair: a controlled menstruation of electricity from their production to your machine. This enables y'all to tattoo at a much steadier and speedier rate than if you lot did information technology without ability. (Remember, the sewing needle and thread with Republic of india ink? Yeah, information technology is much faster than that.)

This I'g sure of: No thing which you lot choose, it will basically work like the rest of the others on the marketplace. Each make and model will offer different concrete features, but its basic purpose is the same.

Do I need a digital display of voltage?

Some power supplies practise not display the volts that are being outputted. If you accept one of these—just a dial with numbers—don't worry. It'll still piece of work fine, but you lot will need to make sure that to make sure it'southward set up properly (come across beneath).

What practise I need to bank check to make sure the machine is mechanically ready correctly?

Bank check...

- for a dime-sized width gap betwixt the car contact spiral and front spring.

- that the prune cord is connected snugly in its appropriate slots.

- that the needle is inserted correctly into the tattoo tube.

These factors will make a huge departure in the performance of your machine. One time you lot have ensured that everything set up correctly, you're ready for the next step.

Digital brandish tin be a little on the pricey side.

Voltmeter approximate (for the ole timers).

Checklist for Setting Up Your Ability Supply

- Turn your ability supply (PS from hither on out) ON.

- Brand certain your pes pedal and prune cord are plugged in the right slots.

- Double-bank check the prune string connection to your motorcar: If all is in society, hold your machine in your tattooing hand and push downwards on the foot pedal. If you don't get the immediate buzz, this probably means that the voltage is not turned upward high enough. Slowly turn that dial until yous go an even, uninterrupted buzz.

- While the auto is running, check visually to run across how far the needle is coming out from the finish of the tube'southward tip. I prefer longer strokes on my liner and shader. I exercise non like to elevate the tip of the tube onto the client's skin and blindly tattoo the line with a short stroke set up liners. With a longer stroke, you are in control of everything the needle does. Information technology takes a ton of practise and feel, but the payoff is amazing. So, if you are running a shorter stroke setting tattoo liner, and then yous should have set your needles to hang over the tube ane/sixteenth of an inch. If you desire longer, then your needle should be coming out almost i/viii of an inch, and you hang your needles just nigh flush with the tube.

- Adjacent, plough your tattoo machine towards you so that you encounter the front view of your machine. You should exist able to see the armature bar nipple that you inserted into the loop of your tattoo needle. It should be moving up and down very rapidly — and so quickly, in fact, that you should not be able to make out the loop on the needle.

- While the motorcar is running, your needle should be coming out one/8 to iii/16thursday of an inch. This is not much of difference, you might remember, but that tiny gap betwixt the skin and tip of needle enables the tattooist to visibly see the lines of the applied stencil.

You tin just barely make out the needles hanging over the tip of the tube.

How to Tune Your Machine Without a Digital Reader on Your Power Source

- Looking at the armature bar nipple, working under an extremely strong source of fluorescent light, if the PS is providing a perfect flow of electricity, yous will notice that the armature bar nipple moves in a figure 8.

- I don't know the exact technical jargon, but basically yous are tuning your auto by the fluorescent calorie-free equally if information technology were timing light.

- If yous do see that figure 8 movement as the tattoo machine is running, so chances are that the machine is ready for tattooing with.

Under fluorescent lights, go on your tattoo car running. If it running perfectly, you lot volition see an obvious effigy 8 on the armature nipple.

Scroll to Continue

Read More from Tatring

Another Way to Tune Without Digital Brandish or Fluorescent Light

If you do not have fluorescent lighting or a digital display on your PS, you will do the final tuning the old-fashioned way.

- Delight first make sure that your equipment is set up up correctly. Once you are gear up, keep your foot pressed down on the foot pedal.

- Begin by turning up your power supply punch until you hear the buzz of your machine. One time y'all hear that fizz, pay attention to how your needle looks as it begins to motion in the up and down motion. You are now tuning the tattoo machine past ear and center. Your machine should run smoothly.

- If your power supply is turned up besides loftier, information technology will sound similar a very angry hornet and at that place will be visible sparks flying off of your contact screw and the forepart spring. If this happens, slowly turn the dial down on the power supply until the sparks take subsided and the car buzzes in a softer mode.

- To test information technology, rub your thumb against the armature bar nipple as the auto is running. The tattoo machine will bog downwards a bit. Merely, when yous remove your thumb, it will instantly resume its steady buzzing noise. If the tattoo motorcar bogs down and will non restart after pressing down on the foot pedal, chances are a contact screw needs to be buffed a bit or yous demand to adjust your ability setting just a bit.

- At present for the visual part of tuning: You are primarily looking to check that your needle is not flopping effectually. If you come across the needle bouncing around in the tube, at that place could exist a few reasons—you might need to add a condom band, you lot may have inserted the needle in the tube incorrect, or your power is turned up too high. And so adjust appropriately. When it's perfect, then information technology is time to tattoo.

Here is my power supply not drawing any electrical current.

This is the ability supply drawing an electric current. Discover the digital brandish and the voltage my car is pulling.

What About Power Supplies With Digital Displays and Memory Settings?

Let's talk very briefly about power supplies that take digital displays and retentiveness settings. I definitely prefer these types of PSs.

- Every bit a addiction, I make sure that my tattoo machines are tuned mechanically first. This works great considering the PS I utilise has retentivity settings congenital in to retrieve which voltage is gear up for a specific type of tattoo car (liner/shader). There are differences and you will see what I mean when you begin and become more confident in your skills and knowledge.

- What I similar the most almost the digital display PS is that you can see how much voltage yous are using and you can also tell if the capacitor is being faulty, because the voltage will different than normal. Too, for the lazy, you can visually ready the power settings.

Online Lessons and Tutorials for the Beginner Tattooist

- Tattoo Auto Mechanics: A basic tour of your tattoo motorcar so you understand the mechanics of its functioning.

- Getting Started, Fix Up, and Ready to Tattoo: A basic step-past-step guide for setting upwardly.

- Tips on Angle Rear and Front Springs for Tattoo Machines: Because getting the correct bend in your springs really does give your tattoo machine the punch it needs to get the job done right.

- Sterilization Procedures in Tattooing: Don't skip this extremely of import footstep.

- First to Tattoo: A list of numbered steps to follow for your first tattoo.

- Tattoo Apprenticeships, How to Get One, and Why You Demand It: Exercise you really need to exist an amateur to become a tattoo artist?

That is the lesson for the day. Remember, if yous take any questions or comments please post them below and I will exist glad to answer whatever questions you may take. Talk to y'all all soon!

—Gman

Questions & Answers

Question: I am currently using that aforementioned verbal ability supply for my tattoo fine art that you lot said y'all were using. I never had a problem until the other day. I was in the middle of a tattoo when all the sudden the voltage jumped all the mode up to nineteen.99. When I tried to move the punch, it either wouldn't modify or it would but start going downwards and back up, and never terminate. How do I fix it?

Answer: Cheque to see if y'all accept a blown fuse, information technology could be as elementary as that.

Question: What voltage should I set my liner at for tattoo shading?

Answer: For starting out, I think your machine should run around 6.6 volts both liner and shader.

Question: What does the foot pedal on a tattoo auto do?

Respond: Your pes pedal is simply breaking the excursion then information technology runs power to your machines.

Question: Is it normal that the power voltage drops a chip, or unstable while hitting the pedal?

Answer: Unstable... pregnant that it fluctuates when but property the pedal? I need more information, please.

Question: What could I employ to make a tattoo gun spring system out of because someone stole all my stuff except a slice of a gun?

Answer: Hardened steel, 20 mm gauge for forepart and back bound... you will have to cut information technology and file it or punch information technology.

Question: My gun only clicks. In that location's no fizz it merely slowly taps up and downwards. What would be your ideas of what'due south wrong?

Answer: Spring adjustment sounds like peradventure also much tension.

Question: Sometimes when I'1000 tattooing the ink doesn't seem to be going in is this considering of the angle I'm tattooing?

Respond: Perchance but the 45-degree angle is what you are aiming for as far as skilful ink flow.

Question: Why does my coil car sound similar a dead battery no matter what voltage it is on?

Reply: A couple of things... rear spring could be broken, You lot are missing an o-ring for your front end spring, Can you lot give me more data?

Question: To check if your tattoo automobile is running too loftier, would effigy 8 on the armature nipple be further apart? And if too slow, closer together?

Respond: Nope yous have it backwards... if machine is running likewise loftier figure viii will be tighter... but too you may have your spring adjusted incorrectly.

Jason Goodrow (writer) from Washington Country on March 04, 2020:

You can go bbn it from the manufacturer more than likely

crazyjay756473055 on February 25, 2020:

where tin i get a wireing diegram for power suppley

Jason Goodrow (author) from Washington State on November 08, 2019:

Jeremy I demand more information well-nigh your situation

Jeremy on November 05, 2019:

The commodities the tightens the contact screw keeps breaking

Jason Goodrow (writer) from Washington State on March 10, 2019:

Opinions allowed but the people of ages past marked their skin with all kinds of material made from from various articles and sad friend it is not all well-nigh art it's nearly the meaning in the truthful tradition of making your body how you like non paying a smoe 100 bucksfor my dad's proper noun that could with Indian ink needle and thread for less than 5 bucks...

Harley Thornton on Apr 30, 2018:

I use the Hurricane Hp2 power supply.

But my biggest issue and for the life of me I can't figure information technology out.. how to go along the ink in the tip equally I tattoo (having to dip into the ink every few seconds) I know that'southward not correct.

And I generally use the nickel and dime trick

Dime for line nickel for shade/colour,

I prepare the power supply unit at half-dozen.8 or 7.3V for shading and packing and by and large 9.4V for line piece of work.

And just a tip for yous beginners out there.

If you have the right V assault your power supply and your machine is tuned correctly you lot shouldn't have much hassle tattooing.

I'm no pro myself this is my fourth twelvemonth in the tattoo industry only I know a lot near it.

The simply thing I stress about is how to keep the ink in the tip? If anyone tin can requite me any pointers that'd be bang-up thanks

Jason Goodrow (author) from Washington State on September 02, 2017:

Sorry it took so long to get back at ya, Rotary machines are something different all together to piece of work with, I have seen other guys work with em, merely colour seems to autumn out which tells me it takes exercise, and probably the correct rotary set up upwardly... I don't have plenty experience to pass on rightfully, only similar annihilation make certain to work on something or someone who wont listen if their is touch up work afterward.

Dave on August 09, 2017:

Hi finding your blog Great , tin you use rotary machines for shading or are they best for lining I accept a stigma , bizarre rotary motorcar simply also take four dragon hawk curlicue machines too which would you suggest to exist the best for begginers

Jason Goodrow (author) from Washington Land on July 17, 2015:

LOL my friend each auto has its own particular sound... just like a car... as long as you lot hear a solid buzz with no sound gaps in that buzz ... that would be ideally what your looking for. But the other variables are... what is the spring stock... what is your tension on your spring prepare... how do yous line leading with the needle or from the tip? Lots of variables to expect at... but too check out the other lessons because how its setup makes the difference.

Jason Goodrow (author) from Washington State on July 07, 2015:

And so I am not sure what the ps15/ and ps17 represent....but if your starting out I would advise ownership a liner and shading tattoo machine. If you cannot determine from the catalog y'all take it may be better to shop around on ebay... or fifty-fifty amazon... tattoo machines are a dime a dozen... but you don't want to purchase the cheapest either. Hope this helps your crusade.

Thank you for the read

Jason Thousand

Jason Goodrow (author) from Washington Land on May 27, 2015:

Human being it really sounds like a basis issue... broken wire (clip cord/foot pedal) If your handy with a voltmeter yous can check electrical continuity and also tell if your power supply is bad. You will need to keep your foot pedal plugged in and make sure you are pressing it when using the voltmeter... make sure that the clip cord that goes to your automobile is not plugged in because that will exist where you will examination with the voltmeter.... if that side tests skillful then switch out pes pedal with where yous tested with the voltmeter. If that side tests practiced as well.. then you take a cleaved wire on the prune cord or in that location is a ground issue on the tattoo machine.... check your washers on the machine... could be a simple issue every bit that.

Hope this helped

Jsngoodrow

Country cropped kanak on May 26, 2015:

Hey give thanks for the response and then ok yep I have a duel digital brandish power supply n normally run information technology around vii.4 pitiful I'm still learning every bit I go and always volition exist willing to learn more give thanks your for the help, and then I only tried to run a new gun to try it out n that won't even piece of work, question now is so as I conect cords all shows light upwards good only once clip prongs become in gun the light won't bear witness upward on the cord low-cal spot conditions I switch from liner spot link to shader spot link the light don't go on like it should exist just that but happens one time I conect gun machine to prune cord prongs cuz upwardly until I conect guns upwards to it all lights show good on power supply displays but conect a gun up n it don't go only pedal calorie-free still shows n power display still at that place merely just the calorie-free for clip string connection goes off even equally I press pedal to run gun if u know any idea on what could exist wrong let me know pls would exist a big assistance I would hate to buy all new gear due north this stuff was only something simple so pls let me know if u got whatsoever idea on my problem mean while thank you for the good feed

Jason Goodrow (author) from Washington State on May 20, 2015:

I would check to come across if you accept any carbon build up on your mail service and front leap... that tends to happen and it can cause your tattoo machine not to run. It will stick...or sometimes spark, or sometimes zippo... so become a slice of emery cloth and clean your contact point (post) and even hit the front jump if you encounter carbon or even rust... IF you encounter rust... get rid of the spring its no skillful. Its rare simply not so rare that a capacitor on your tattoo auto blew... yous volition know this though because it would have fabricated a pretty good popping sound, and probably a small light prove. Same gig check all points that electricity goes through... your cord finish could be loose, or bad, aforementioned with your foot pedal. If yous think every matter is in order then start in on the power supply...light comes on but do you have a voltage display? If and so what do you normally run your power settings at... Permit me know if this helped... thank you for the read!

jsngoodrow

country cropped kanak on May 20, 2015:

Hey so deplorable but wondering if my power supply lights up n seems to run fine just none of my guns wont run at all on it n ive used them alot before northward had them for a skilful while northward did quite a few tatts with um north at that place yet quit new only haven't used um in a few months, i was just wondering if u could assist me out n let me know what could be the problem on that.... ne ways hopefully someone tin aid thankyou -country cropped kanak

Jason Goodrow (author) from Washington Land on Apr fourteen, 2015:

Woo Hoo! well accept fun learning its pretty proficient stuff.

Amber on April 14, 2015:

Actually I merely fixed it! Cheers for the fast replies and for posting your very helpful lessons!!!

Jason Goodrow (writer) from Washington State on Apr fourteen, 2015:

Also check your rear bound for also much tension... easy matter to forget if your new to messing with your springs.

Amber on April 13, 2015:

Yeah I've been messing with the contact screw as well equally the front leap in gild for it to run. My machine won't run if it's nether 10...why is that?

Jason Goodrow (author) from Washington State on April thirteen, 2015:

Ahhh I see... so maybe check your forepart spring... sounds like to much tension and it wont release it until you mess around with the contact screw. Trust me if your new to this you're gonna probably be like what the hell is he talking near, besides what is your power ratio when your running the tattoo car on your power supply... if it has a screen.

Bister on April 13, 2015:

I'k pitiful I wasn't very clear haha what I meant was that if I accept my pes off the pedal and press on it again information technology won't turn on once more I would have to do that whole contact spiral routine

Jason Goodrow (writer) from Washington State on April 13, 2015:

Hi there Amber, so read through this lesson over again, just I volition tell you lot that you demand to simply go along your human foot pressed on the pedal to keep the auto running... this is just so you have control over when the tattoo auto runs, or if you lot just need to cease in full general to wipe your client off. Delight read through... I have lessons talking about how to ready your machine up from the very beginning. Hope this helped!

Thanks for the read!

Gman

Amber on April 13, 2015:

How-do-you-do, I wanted to know why my tattoo machine shuts off afterwards I take my foot off the pedal? To make information technology turn on again, I keep my foot on the pedal and I screw the contact screw to the end of the front end bound until information technology clicks and I screw information technology back to the heart of the front bound and information technology works fine again. What should I do to make my tattoo machine keep on running???

Jason Goodrow (author) from Washington Land on March 21, 2015:

Bob please refer to my other lessons, in that location is a ton of in formation on that specifically, pics included.

Thanks for the read

Mike on October 17, 2014:

hey M-Man, great read, and commend you for helping out the newbies.

Jason Goodrow (author) from Washington Country on September 20, 2014:

Send it back if the fuse is not blown in the Power supply... that could be all information technology is.

babyhatchet on September 17, 2014:

I just got my machine and I hook it up and there is no ability getting to the machine I am not certain what to do

Jason Goodrow (author) from Washington State on September 09, 2014:

Y'all may demand to check the capacitor that is on the car, it may be incorrectly soldered or faulty altogether... showtime matter though is cheque with a voltmeter as you printing down on the foot pedal and see what the actual voltage is without the machine fastened, this should tell you that your Ability Supply is proficient or bad.... promise this helped!

Mike on September 09, 2014:

I only bought a new clip cord because my machine was not getting any power but its still not getting enough power to run the machine what else could information technology be?

Jason Goodrow (author) from Washington State on August 04, 2014:

Non sure what the electric variances are, but well-nigh tattoo shops will run 110v for their power supplies. So first get me the variances and tell me a few things.

What blazon of tattoo machine are you using

What is your Ability Supply set at

Are your springs adjusted correctly

As far as lining general dominion for outlines is 7-viii liner bug pin or long taper which ever y'all prefer and lining should run at vi.vii volts

Besides check the other lessons I have posted your needle bar should go in one way only possibly that's it/ cleaved spring... never know

And then information is what I need please post if serious.

Cheers

naidy on Baronial 04, 2014:

Hi I bought a new kit from one of the sites I'g from southward africa I have a small problem with shading an lining I'chiliad not certain wat voltage shud I use wen shading an how many needles shud I use an wen out lining I also have a trouble with ink non chatching I have to go over my outlines twice in order to get it dark an please help

Johne581 on July 16, 2014:

My brother recommended I may similar this website. He used to be totally right. This mail truly made my mean solar day. Yous can non consider simply how and so much time I had spent for this info! Cheers! dedcdacedeac

Jason Goodrow (author) from Washington Land on April 09, 2014:

Your liner will have a shorter front spring and a bit of a steeper pitch well-nigh 45 degree angle or so and your shader volition have a longer front end jump and the pitch is more shallow, more like 30 degrees... hope this helps, too take a look at my other lessons lots of good information!!!

kaki hemam on April 09, 2014:

How can we differentiate the same ii machine equally liner & shader..actually I bought 2 machines so still confusing i.e which machine should be linear/which motorcar should exist shader..... pliz help me out of this...

Jason Goodrow (author) from Washington State on February 21, 2014:

Hope you lot take the receipt...

jonh on January 08, 2014:

first of all i want to cheers for your help,

my respect to you....aw a beginner i bought ii tattoo machines one shader and ane liner. I had the impression that both shader and liner contact points angles had to be at 1 o'clock,am i wrong??? .... and one more thing that may seem airheaded, I'one thousand from europe and I have exactly the same power supply as yours, two have to tattoo in same volts equally you? 6 -6.viii ?? go on up the good work

Jason Goodrow (author) from Washington Land on September 17, 2013:

Sounds like your jump tension is to business firm... you may demand to weaken that spring only a bit... don't overdo it or you could suspension it! Permit me know if this helps or need more information

Jason Goodrow (writer) from Washington State on September 15, 2013:

not sure exactly but it almost sounds like you are grounding out somewhere in your equipment... faulty wire in the pedal, connection ports for your pedal in the p.s. it'self... not to say it could be a broken spring... there are many variables... too check but maybe for some reason your ports are specific for what is plugged into it.... let me know if this helps!

steven on September 15, 2013:

hey basically ive had my tattoo equipment for a couple of months and ive never had whatever problems running machines before today when i went to fix up i plugged everything in perfect and now every time i apply pressure to the foot pedal my volts seem to be slowing/going down im so confused as to what is going on then could you delight help me

thanks alot

steven

Jason Goodrow (writer) from Washington State on July 26, 2013:

When I hear someone say practice paper I am assuming skin. You left out some key components that will help maybe problem shoot your trouble. First.. great your machine is tuned to what yous say merely when running what was the voltage running at, also man, your needles could exist inserted wrong... that is a very mutual mistake, next is what shading manner were you using? and what type of shader ( rounds or magnums ), and then adjacent again especially coming from a kit what type of ink... these are your main concerns. Hope this helps!

Marking on July 25, 2013:

Hey, I accept a question. I bought a set not besides long ago, and have started practicing on practise paper, and my bestfriend let me exercise one on him, just when I did it on peel, everything was tuned correctly, On my power supply I used around half dozen.5 for Lining and vii for Shading. The machines seemed to sound correct and everything was running smoothly. But when I started to practice it on his skin, I found information technology hard to outline the contour line of his tribal piece which took multiple turns to run over every line just to make information technology stay in his skin. Afterwards, I started shading it in with black, and it took going over each shape roughly 6 or 7 times just to make that stick in his skin. Now afterward I was done, he took a shower the next day, and when he wiped it off, the shapes have spots that are not fully colored in, and the lines weren't fully there. What can I do to make prissy, solid one sweep lines? And how tin can I shade better with just normal black, or any color for that matter?

Jason Goodrow (author) from Washington Land on July 21, 2013:

Pare textures and how your machine is set upwards dictate this number. I don't have a specific magic number because many of tattooists use different machines and different power supplies, along with different shading techniques, this does not include ink type, spring tension, what kind of contact bespeak y'all are using (contumely, copper, or steel). Once you lot have tuned your machine though what ever the voltage number is should be consistent through the tattoo, keeping in mind you should never be running above seven volts unless you are pushing a massive grouping of magnums, and if you are but offset, you lot will want to stay away from those until you have plenty of experience with a variety of shading techniques. Hope this helped!

Jason Goodrow (author) from Washington State on March 27, 2013:

Almost of this volition depend on the size of the rounds and magnums, only ideally yes it should be consistent voltage that you run your machines at.

Begner on March 26, 2013:

I have this question.. circular shaders and magnums run at the aforementioned voltage? or different?

Jason Goodrow (author) from Washington State on March 25, 2013:

Once more if anyone is tuning your machine and your using more that 7 volts, I would exist very hesitant on using the equipment. Well-nigh professionals volition tell you the same thing I am. If you started off cheap so yous may accept ended upward with a bunch of equipment that does not work. It is rare but I take seen it on several occasions. If it were me I would only start from the commencement, set your machines up, as I suggest in the lessons, also bank check for that carbon build up especially afterwards having run your tattoo auto equally you accept. Skillful luck! Proceed me posted.

Jason Goodrow (author) from Washington Country on March 24, 2013:

There could be a few bug, and its not always going to be ability supply related. Every professional person tattooist I have ever met run their machines in the 6.0 - 6.8 range. If you lot are having issues with your automobile non running at these lower voltages and then information technology could be related to the gauge of your spring, your contact betoken, is it brass or metal? Have yous checked to make sure the contact point has no carbon build up from running at high voltage? Too if it is a cheaper machine information technology may simply run at those college voltages simply the quality of the tattoo will be hindered. There are many things to pay attention too. First make sure that your contact points are at the right angles as I suggest in the mini lessons. Your liner will be at ane 'o' clock and your shader will be at about iii 'o' clock. Liner with a dime width gap and your shader with a nickel width gap. Trust me I asked these same questions and I fifty-fifty doubted the information. Most cases it wont be your ability supply that is the problem it volition be how your machine is tuned. Promise this helped, please revisit those lessons they might have more to add. Thank you for reading!

Jason Goodrow (author) from Washington Country on January 25, 2013:

Hey at that place border Craog B basically had the aforementioned question equally you, so follow the instructions I gave him, see what I can do for you guys.

Jason Goodrow (writer) from Washington State on January 04, 2013:

Hullo there Despina, if your similar me and can beget information technology, buy a new one. I have never encountered that problem myself merely a few things practice come to heed. Sometimes, non frequently mind you, how the electricity flows from the wall through the ability cable and then the "regulator" that steps downwardly amount that volition flow through the power supply itself, those can go bad after years of employ, and of course most things like that are made in prc because how cheaply they are manufactured over in that location. Some other thing is some of those P.S. take fuses and it may be fix to pop. I have torn this particular p.south. autonomously too and made comparison to the other ones I use. If yous are savvy, accept it autonomously and check to make sure you lot take no crossed wires, sometimes things settle with age. Next question for you is how long have y'all had this unit, considering I had to order a new cable for it, and I accept been using information technology for better than 7 years. Hither is the adapter type I institute for it, hope this helped.

model:ADS-24S-12-1224GPCU

INPUT:100-240V 50-60Hz

OUTPUT:12 5

Let me know if this helped or not!

Jason Goodrow (author) from Washington State on September 22, 2012:

In that location are several techniques you need to apply to doing smoothen straight lines. A lot will begin past the tube size you are using... I employ a 1' tube grip this tends to give me better control over line shakiness especially with curved lines. Adjacent matter with line work.... get at least a iii bespeak stretch, it will help the ink enter the pare more smoothly as you work the tattoo, so there are a few tips that volition have care of a few things... a note though information technology takes time to build the strength in your paw so warm upwardly first become a pen and put it in your car and practice the stencil by hand you volition be pleased with the results, I did it and if I have not tattooed I do detect a style to warm my tattoo hand up before going to work. Promise this helps.

Gman

Mario on September 05, 2012:

Hi I have a question? I would like to now if you have any tips or ways I can practice to make perfect directly lines. Im not bad but on tribal ho w at that place is long lines I have have a hard time keeping direct

Jason Goodrow (author) from Washington Country on August 14, 2012:

Cool, 8 does seem high to me likewise. Try letting the machine run direct for a minute with no interuption. Then get ahead and conform downward, continue in heed it does not need to quickly penetrate the skin like the liner so by sound they are going to be different. Let me know

G-Man

sky on August xiv, 2012:

hi, thank you for the advice, information technology's actually a shading machine that I can't seem to set upwards right, I've managed to get it to work without the sparks after I discovered my ps was cleaved and got it replaced notwithstanding it only seems to piece of work on a very high setting (around 8ish) whereas my liner works at around four, I'm manifestly doing something incorrect I just don't know what.

Jason Goodrow (author) from Washington State on August 12, 2012:

Howdy there Heaven... so this sounds like a machine set up up upshot. This may take a flake more to explain without some type of pic. So Be patient. If this is a lining automobile accept a wait at the angle or pitch of your contact screw. My lining machines are set up at virtually 2 o'clock so if the pitch is off this can cause bug... also bank check that the contact screw is striking near the very edge of your front end spring besides if it is ready too far dorsum same thing volition happen. These are a few things to accept a peek at and similar I said I have a machine I have to replace a bound on so I will go alee and produce this lesson for anybody. Hang in there!!!

Jason Goodrow (author) from Washington State on Baronial 12, 2012:

Hi Adam... to answer a few of the questions you lot posted. Your needle at total penetration should only enter the third layer of the dermis, or in unproblematic terms about an 1/eight inch. I accept been tattoing a few years now and I adopt to work off my needle so that means I let the needles hang out the end of the tube almost a 1/xvi of an inch, and and so from there I control the depth the needle is entering the skin through a technique I learned from another artist. So as your motorcar is running it should wait like your needle is coming out almost a 1/4 inch... this is more than advanced technique... for begginers I suggest breaking out some type of melon or potato type object and practise on that a few times until you are able to work the ink into it with out too many problems. Go on me posted

sky on August 10, 2012:

hi, I can't seem to i of my machines to work properly I either go sparks or zilch, I'm a beginner so not sure how to remedy this, please help

adambritsch on Baronial 10, 2012:

i am just a beginner with tattoos and i am not an artist or even looking to become i, im just using my gun on myself and figuring things out. i am a little confused about how deep the needle should be penetrating and how. it sounds like the pollex rule is 'dime for lines, nickel for shade'. if that is correct, and so my question is this; do you lot fix the tip and tube upwardly and then that you can drag the tip over the pare, or should have that 1/16". it sounds like even in your write upwardly, yous were hesitant to mention those depths particularly for rookies. cheers for the post also, it was helpful. -Adam

Jason Goodrow (author) from Washington State on Baronial 02, 2012:

So first off lets not tattoo on anyone else until you have figured your equipment out... it sounds like you lot basically put your equipment together wrong and practice non have your ability settings correct. The needle snagging ways not enough punch... either jump is bad or ability supply is non fix correctly. The tat scabbing and then but peeling off suggests spring problems once again and so start from scratch do non tattoo anyone else until y'all have got this all figured out and check out my lessons on how to become your tattoo motorcar gear up up just in case you lot missed something.

Continue me posted

Heather on August 02, 2012:

Just got a new kit and it seems like the needle snags, then afterwards the tat scabs and peels off... It'due south not taking & no matter what it is snagging.. What tin I practise or should I exist doing to fix this?

Jason Goodrow (author) from Washington Land on July 24, 2012:

Check your springs, and contact points

How Make Tattoo Power Source,

Source: https://tatring.com/getting-tattooed/Interested-in-Tattooing-Power-Supply-Points-and-Tips

Posted by: vincentsparleathe.blogspot.com

0 Response to "How Make Tattoo Power Source"

Post a Comment